Discovering the Role of Metal Foundry in Automotive Manufacturing

Wiki Article

A Comprehensive Overview to Metal Casting: Benefits and Services Offered by Foundries

Metal casting is an important process in numerous sectors, providing various advantages through the services of foundries. These facilities change molten metal into long lasting and exact parts, providing to details customer requirements. By employing advanced modern technologies, shops guarantee high quality and efficiency in manufacturing. The ins and outs of metal casting and the diverse methods entailed raise important inquiries concerning its function in modern-day manufacturing. What developments lie ahead in this important area?Recognizing the Metal Casting Process

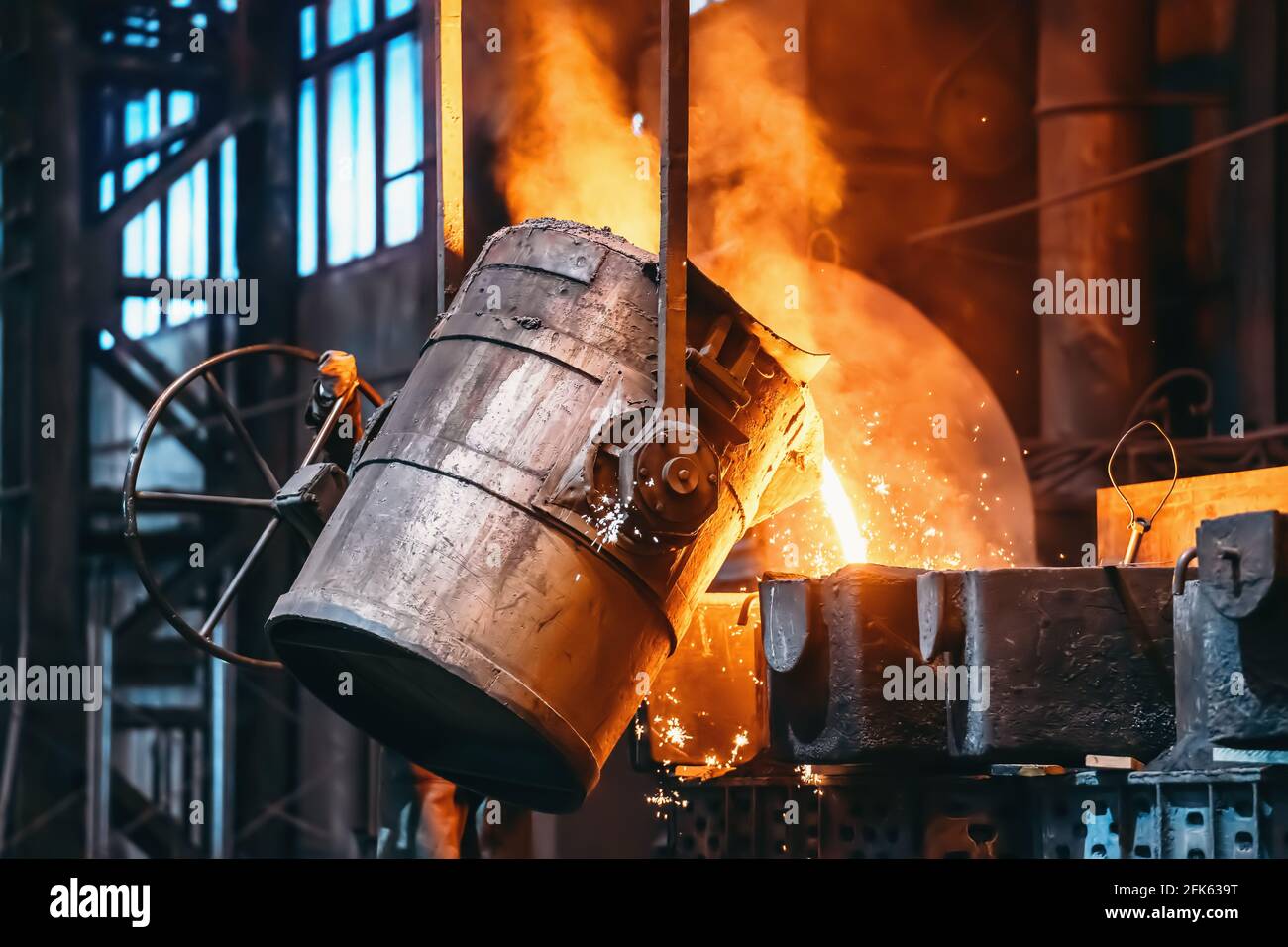

The metal casting procedure is a fundamental technique utilized in producing to develop complex forms and elements. This approach includes putting liquified metal right into a mold designed to create the wanted item. The process starts with pattern development, which functions as a theme for the mold. Aluminum Foundry. Numerous materials, such as sand, metal, or ceramic, are utilized for mold-making, depending on the particular demands of the casting

Once the mold is prepared, liquified metal is put into it and permitted to cool down and solidify. After solidification, the mold is removed, exposing the actors component. Various strategies, including sand casting, investment casting, and die casting, are employed, each fit to various applications and products. Quality assurance measures, such as assessments and screening, are necessary to ensure the end product meets specifications. On the whole, the metal casting procedure plays an important role in generating components for industries varying from vehicle to aerospace.

Trick Perks of Metal Casting

Metal casting supplies considerable advantages that make it a recommended manufacturing technique in numerous industries. Its design adaptability and precision permit elaborate shapes, while affordable mass manufacturing boosts efficiency. Additionally, the adaptability and stamina of materials made use of in casting add to the sturdiness of the final products.Layout Flexibility and Accuracy

Launching amazing style versatility and precision, metal casting permits designers and engineers to develop intricate shapes and features that would certainly be difficult or difficult to attain with various other manufacturing methods. This capacity makes it possible for the manufacturing of intricate geometries, inner frameworks, and great details that enhance item capability and visual appeals. Additionally, different casting methods, such as sand casting, financial investment casting, and die casting, give further alternatives for customization, accommodating varied product buildings and project demands. The flexibility of molds allows alterations throughout the style phase, simplifying the change from idea to final product. Inevitably, metal casting stands out for its capability to supply high-precision components, making it a vital process in markets ranging from automobile to aerospace and beyond.Economical Automation

Cost-efficient mass production stands as one of the key benefits of metal casting, making it possible for producers to create large amounts of elements at a reduced cost per unit. This performance occurs from the capability to create intricate mold and mildews that can be recycled numerous times, significantly reducing arrangement and operational expenses. Additionally, metal casting processes, such as sand casting and die casting, allow for high throughput, making it viable to satisfy the needs of massive production runs. The minimized material waste and power intake further enhance price savings, making metal casting an appealing alternative for sectors requiring bulk components. On the whole, the affordable nature of metal casting placements it as a preferred technique for suppliers going for financial performance in their manufacturing procedures.Product Adaptability and Strength

One of the standout attributes of metal casting is its impressive material versatility, which enables using a wide variety of alloys and steels. This adaptability allows producers to pick materials that ideal match their certain applications, from aluminum and bronze to iron and steel. Each metal supplies special homes, consisting of differing degrees of strength, rust resistance, and thermal conductivity. Metal casting can produce parts that satisfy rigid performance requirements across diverse sectors, such as automotive, aerospace, and building and construction. Furthermore, the strength of actors steels can be enhanced through numerous treatment processes, ensuring longevity and durability. Aluminum Foundry. In general, the mix of material versatility and fundamental toughness makes metal casting a favored choice for producing high-quality componentsKinds Of Metal Casting Methods

Metal casting includes a selection of methods that deal with different manufacturing requirements and product properties. Typical approaches consist of sand casting, which makes use of a sand mold for complex forms, and investment casting, recognized for its accuracy and surface finish. Die casting is an additional technique that employs high-pressure shot of liquified metal into molds, ideal for mass manufacturing of little components.Covering molding provides a faster alternate, utilizing a resin-coated sand to produce thin-walled mold and mildews, while lost foam casting enables elaborate layouts without the demand for a core.

Additionally, continual casting is utilized for producing long pop over here areas of metal, such as bars or sheets, by strengthening molten metal in a continuous process. Each strategy is and presents unique benefits picked based upon variables like the called for detail, production volume, and product kind, ensuring superior results in metal manufacture throughout various sectors.

The Function of Foundries in Metal Casting

Shops play a crucial function in the metal casting procedure, working as the centers where liquified metal is transformed into ended up products. These specialized establishments are geared up with the essential tools and modern technologies to handle various steels, ensuring top quality outcomes. Factories are accountable for numerous critical functions, including thawing the metal, putting it right into molds, and permitting it to solidify.Additionally, they preserve stringent safety and security and environmental requirements to safeguard workers and minimize eco-friendly impact. Knowledgeable professionals and designers collaborate to enhance casting procedures, boosting performance and reducing waste. Foundries likewise take part in high quality control steps, guaranteeing that the final items fulfill certain resistances and specifications. This quality control is important for sectors that rely on precise parts, such as auto and aerospace. Because of this, factories add considerably to the total production landscape, enabling development and development throughout different sectors.

Customized Metal Casting Solutions

Customized metal casting services supply tailored layout solutions that meet specific customer demands. These services likewise provide material option competence, guaranteeing the ideal metal is picked for the desired application. Such flexibility and understanding boost the general top quality and efficiency of the final product.

Customized Design Solutions

Customized design solutions in metal casting supply makers with the flexibility to develop parts that meet particular performance and aesthetic demands. Factories provide customized services that permit customers to define dimensions, shapes, and surface coatings to attain preferred end results. This customization procedure often consists of partnership between engineers and designers, making certain that the final products align with operational requirements and sector requirements. Advanced modern technologies, such as computer-aided style (CAD) and simulation software application, enable accurate modeling and testing of elements prior to manufacturing, decreasing errors and improving efficiency. By leveraging tailored Read More Here layout remedies, organizations can maximize functionality while reducing waste and costs, ultimately resulting in an extra one-upmanship in the marketplace. This adaptability is crucial for markets needing one-of-a-kind applications and specs.Material Choice Expertise

When picking products for metal casting, expertise plays a vital duty in making sure that the ideal choice straightens with both performance demands and cost-effectiveness. Shops employ proficient specialists who comprehend the properties of various steels and alloys, enabling them to suggest suitable products for details why not try this out applications. Elements such as strength, rust resistance, and thermal conductivity are thoroughly thought about to fulfill the customer's demands. Additionally, industry trends and innovations in product scientific research educate these decisions, making it possible for factories to remain affordable. By leveraging their knowledge, shops can assist customers in guiding with facility product choices, eventually causing improved item top quality and minimized production costs. This specialized expertise is crucial for attaining successful outcomes in custom-made metal casting solutions.Quality Control in Metal Casting

Quality assurance in metal casting is crucial to assure that the end products meet the needed specifications and performance criteria. Factories utilize a range of techniques and techniques to assure the finest quality of actors parts. This process begins with strict material assessments, validating that raw materials adhere to industry requirements. Throughout the casting procedure, real-time tracking and testing are performed to evaluate specifications such as temperature, mold honesty, and dimensional precision.

Applications of Metal Castings Throughout Industries

Metal spreadings play a critical duty in different industries, offering as the foundation for numerous applications. In the automobile sector, cast components such as engine blocks and transmission real estates are essential for automobile efficiency and dependability. The aerospace industry depends on accuracy castings for important components that ensure safety and efficiency in trip. Furthermore, the building and construction industry makes use of metal spreadings for fixtures, installations, and architectural elements, improving the resilience of structures and facilities.Furthermore, the power field take advantage of spreadings utilized in turbine blades and other equipment important for power generation - Aluminum Foundry. The medical area likewise makes use of metal castings in tools and instruments, showing the adaptability of this production procedure. Generally, metal castings are indispensable to the performance and improvement of diverse markets, showcasing their significance in modern technology and framework advancement

Regularly Asked Questions

What Materials Are Generally Made Use Of in Metal Casting?

Typical products used in metal casting consist of light weight aluminum, iron, bronze, steel, and brass. Each product provides unique homes ideal for different applications, allowing producers to choose the ideal alternative based upon toughness, weight, and corrosion resistance.How much time Does the Metal Casting Process Commonly Take?

The metal casting process usually takes several hours to a few days, depending upon variables such as the intricacy of the layout, kind of metal used, and the details casting method used by the shop.

What Is the Environmental Impact of Metal Casting?

The ecological impact of metal casting includes energy consumption, exhausts, and waste generation. Factories usually execute steps to alleviate these results, such as reusing materials and making use of cleaner modern technologies to decrease their environmental footprint.Can Metal Casting Be Provided For Small-Scale Projects?

Metal casting can certainly be performed for small-scale tasks. Numerous foundries deal with such requirements, providing customized remedies that accommodate minimal production runs while maintaining top quality and precision in the end products.What Are the Precaution in Metal Casting Foundries?

In metal casting shops, precaution include individual protective equipment, proper air flow, training on equipment usage, emergency procedures, normal maintenance checks, and adherence to sector safety requirements to lessen dangers connected with molten metal and hazardous products.Furthermore, metal casting processes, such as sand casting and pass away casting, permit for high throughput, making it feasible to meet the needs of massive manufacturing runs. One of the standout attributes of metal casting is its remarkable product convenience, which permits for the use of a vast array of alloys and steels. Furthermore, continuous casting is utilized for producing lengthy areas of metal, such as sheets or bars, by solidifying liquified metal in a continual process. Foundries play a critical duty in the metal casting process, serving as the facilities where molten metal is changed into completed products. Typical materials used in metal casting consist of aluminum, iron, brass, steel, and bronze.

Report this wiki page